Services

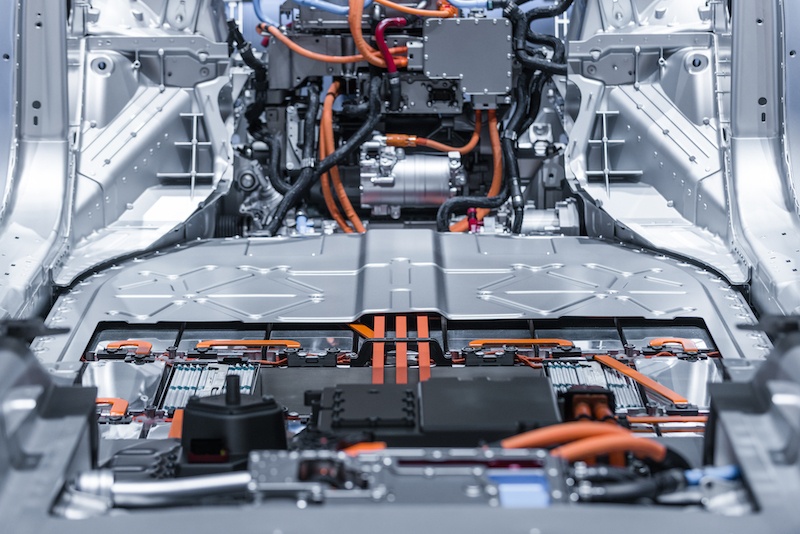

We help our clients to create the E-powertrain concepts architecture, defining the specs of High Voltage components in the E-Powertrain engineering area. We manage the all life cycle from elicitations to final agreements in this four areas.

OEM’s/TIER’s E-Powertrain specification is organized into next quadrants divided into four parts:

Non Safety Functional

DC/DC:Convert DC energy to DC energy.

Inverter: Convert DC energy to AC energy.

Measurement and determination functions.

Deratings.

OBC: Protocols&Norms

Protection functions.

Non Safety Non Functional

Environmental (Humidity, Temperature, Vibration..).

Performance (Efficiency, Dynamic response…)

State machine (sleep, wake-up, active…)

OBC: Protocols&Norms

Mechanical requirements (housing, weight, dimension, interfaces…)

Safety Functional

ISO 26262 see the Functional Safety section.

Safety Non Functional

Warning Signs

Isolation resistance

Touch current

De-energization

Capacitive coupling

Equipotential bonding